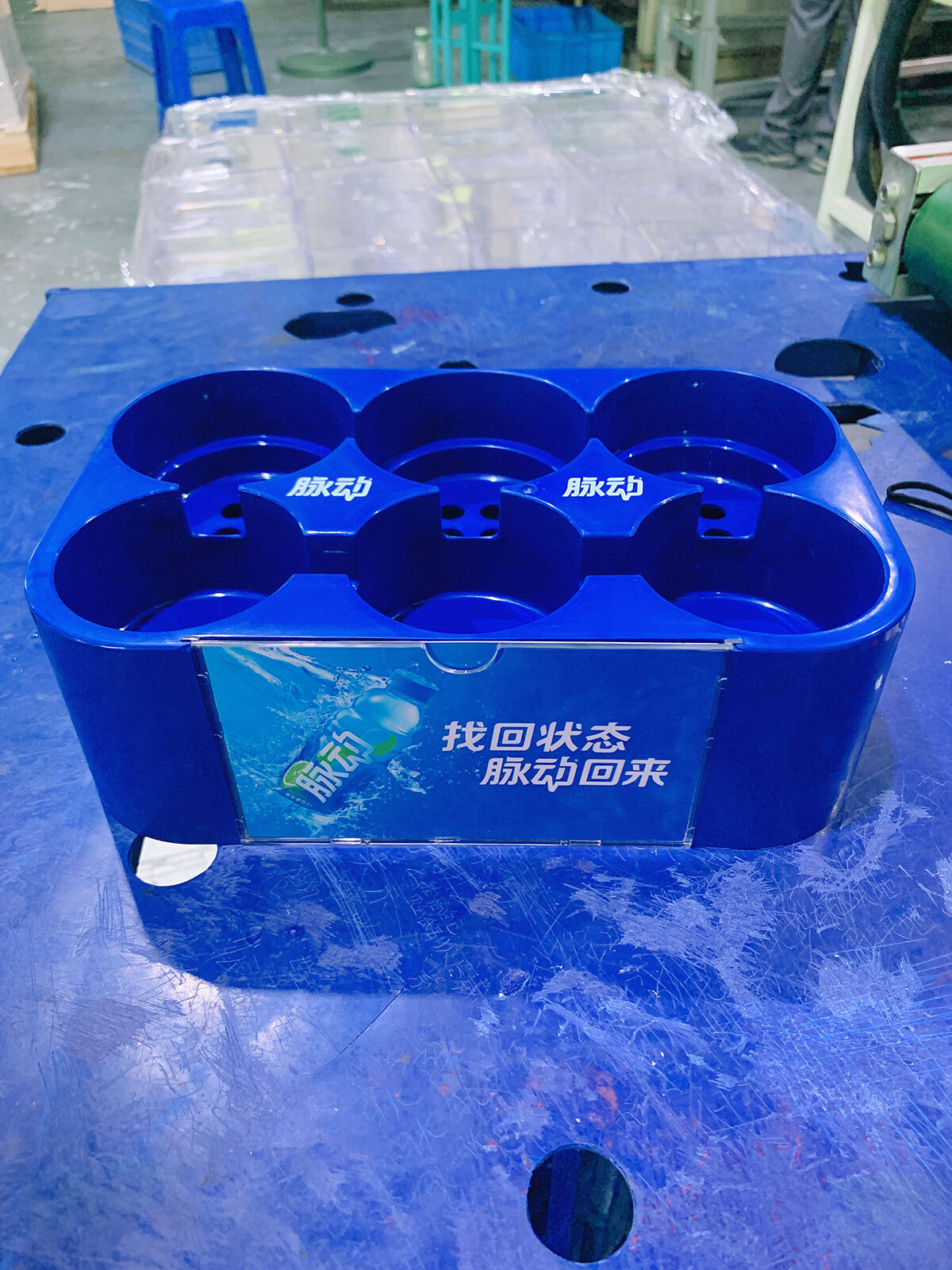

floor display stands mold

Floor display stands molds are essential manufacturing tools designed to create versatile retail display solutions. These precision-engineered molds incorporate advanced injection molding technology to produce durable, attractive display stands that effectively showcase products in retail environments. The molds are crafted from high-grade steel materials, ensuring longevity and consistent production quality. They feature sophisticated cooling channels that optimize the manufacturing process, reducing cycle times while maintaining product integrity. The molds are designed with multiple cavities to enable efficient mass production, incorporating adjustable features that allow for various display stand heights and configurations. Advanced surface finishing techniques are applied to ensure smooth, professional-looking end products. These molds can accommodate different materials, including ABS, acrylic, and polycarbonate, making them versatile for various retail applications. The design includes strategic gate locations and runner systems that minimize waste and optimize material flow, resulting in high-quality display stands with minimal defects.